|

"A Cowboy in the Meat Business"

Interview with Mel Coleman, Sr. Colorado ranch produces meat free of growth-promoting hormones, anti-biotics Photo Series by Nic Paget-Clarke Denver and Saguache, Colorado

Hormones I was on the stage, on the panel. I said "No, chicken's taken over and we've got some problems. Our product is inconsistent for one thing and frankly, I don't want to get in a fight with you, but we've just been through this D.E.S. rap and people have got a problem with using chemicals in food. Now why don't we change our ideas a little bit and fight those chickens."

Well it didn't happen. So in '79 I thought "Well heck, I'll keep the cattle one more year and get in the business myself and try to sell it." But that was just a cowboy getting into the meat business, that was just terrible. Couldn't sell it. I was going to sell intact bulls at first because I thought it was wrong to rip out the hormones then stick them back in his ear in the form of an implant. In Motion Magazine: What is an implant? Mel Coleman Sr.: Well, it's a pellet, the size of a saccharin tablet or half an aspirin. It contains either estrogen or testosterone or progesterone, depending on the sex of the animal. It's in the ear and it secretes estrogen (or other hormone) into the body over a period of about 30 days. Some last longer but it finally melts away. It's like a steroid in young athletes, it builds red muscle. The original hormone pellet, DES, was found to be harmful to fetuses in pregnant women and was banned back in `75. But the chemical companies were hot on the trail of having new ones, so now the new ones they claim are safe. They were ready with them right after DES was banned. Antibiotics After World War II when I got out of the Navy and went back to the ranch, penicillin became available commercially. Penicillin was discovered in the late '30s. It was extensively used in World War II. After that it was available for veterinarians to use. One c.c. of penicillin in 1946 was worth about $9 and that was worth more than the calf was. But it would get a sick calf up just like that. It worked for people and animals. In the spring of the year you could go into Doc Keating's office in our little town of 600 and say "Doc, give me a shot of penicillin, I can't get sick in the spring. There's just way too much work to do and I just can't get the flu." And it would just get you well immediately, just a wonder drug. The industry, the whole meat industry, birds clear through to beef, started putting antibiotics in the feed just to cut down on the sniffles. Then they found that antibiotics in the feed yard made the animal grow faster. They said "Wow, that's really great." Doctors and ranchers and veterinarians were using this theory: if 1 c.c. is good, then 5 ought to be better. That's just human nature. Same way with fertilizers. If 100 lbs./acre is good, then 500 is better. Going It Alone I thought, if you can build a company to attack all of those problems concerning hormones and antibiotics that some people are worried about, you'll have customers. But they're scattered all over. In a town of 500, there may be two people who are really worried about it. Or there may be a third person that's allergic to antibiotics. (If small residues of antibiotics are in the food that they eat, some people have an allergic reaction.)

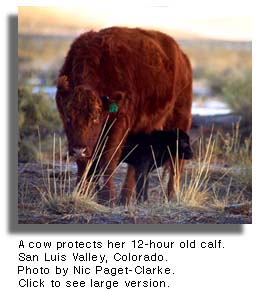

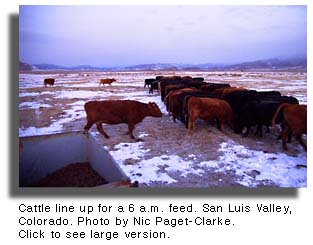

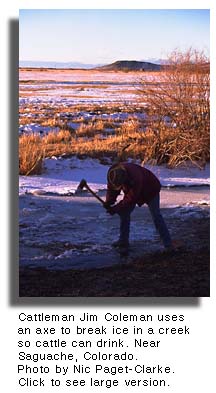

(Editor: In 1981 Coleman struck its first major deal with a California-based natural food store and then made distribution deals with Bread & Circus in Massahcussetts, Alfalfa Markets and Wild Oats in Colorado, Whole Foods Markets in Texas, and Fresh Fields in Maryland). I would like to change the whole agricultural system back to where it's sustainable and environmentally sound. So, it just started growing. We're here in Denver now and we're doing probably $60 million a year in sales and we started from zero. The business has expanded and we've got probably 350 ranches in 17 states that are raising cattle for us because I don't raise them all. We've got 1,200 that have signed up and want to participate if I could just sell more meat. In Motion Magazine: Where is the Coleman Ranch? Mel Coleman Sr.: It is in the San Luis Valley here in the Rockies near Saguache (a Ute name meaning blue earth). It is a high valley. I call it the Valley of the Eights; it's 8,000 ft. high, about 80 miles each way. It only gets eight inches of precipitation in a year, which is less than the Sahara Desert gets. It's got a vast amount of underground water so it's not a blowing desert. And there's a little airstrip there at Saguache that's 8,000 ft. long. I wanted to develop the whole business in Saguache just to have a little rural development, but I found out that it's hard to do business on a party line. Also you don't have any trucking, you don't have the facilities of a publishing company. You just can't do it. You have to do it in town. In Motion Magazine: What process do the cattle go through? Mel Coleman Sr.: These cows wait around on our meadows around Saguache there. Pregnant cows waiting around to have a calf. Then in February and March, they start calving out here on the dry ground. When we get about 100 we'll move them off and work them. We call working them as this: when they're about a month old, we'll put a tag in their ear, which is an ID tag. Then we brand, castrate, de-horn and give them their calf lick vaccinations, which are not antibodies, they're a vaccination similar to DTP shots that we give our kids when they're born.

Then they go out on the range when they're about 500 lbs. In the fall of the year, we'll wean them, separate them from their mothers. They'll be fed differently for the meat that they will eventually provide. The mother cows, we'll work them and then they'll last on the ranch along with the bulls about 8-10 yrs. Out of these older cows we'll get probably 8-10 calves, one a year. When they wear out and get oldwe don't sell Coleman beef from cows and bulls because the meat is tough, like an old bull elk that you kill in the hunting seasonwe take them to a sale barn and they end up in processed meat. They end up in Arbey's or fast-food restaurants like McDonald's. Anyway, the younger animals are weaned weighing say 500 lbs. The next 4-5 months they'll spend just growing. They'll grow up to 800 lbs. when they will be put into the feedyard. In the feed yard we demand that each animal have 250 sq. ft. of space apiece (40% more than in conventional feed yards). Here, we put another red tag in their ear so that the federal inspector at the slaughter plant can identify them quicker than he can by reading that little white ear tag. The cattle are in this feed yard for 90-120 days, depending on demand. After they reach a weight of about 1,150 lbs., they're taken by truck to the slaughter plant. At the unloading, there's a fellow in a white hat who is the federal inspector. He's looking to see if these are indeed Coleman-fed cattle. He's looking to see too that they're healthy. There's also a fellow who is the Colorado brand inspector who is looking for that double circle brand because that's the personal brand of Coleman Ranches in Colorado. He wants to make sure that Coleman isn't selling one of his neighbors' cattle. That's the final look before the hide comes off. A third fellow there is the truck driver; he's delivering the affidavit from the feeder to the federal inspector saying that these cattle have indeed been fed the Coleman way. He also carries the bill-of-lading billing for these trucks for their service. After they are slaughtered, they come to the boning plant here in Denver and the packing plant. The meat goes out from here in a box to our customers.

In the retail store they break open the plastic bag and cut pieces of meat off as they need it. Hazard Analysis and Critical Control Points Now all during this time we have a HACCP system in placeright from conception to consumption. HACCP is an acronym for Hazard Analysis and Critical Control Points. It is system that the government actually started for the space program, a lot of critical control points in any kind of production system. For instance, in our system when a calf is born it's critical that he gets that first milk from his mother called colostrum which is full of antibodies. That's a critical control point for a live animal. When the calf is weaned, that's a critical control point because it's stressful for that young animal to be taken away from his mother. In a meat plant or in a slaughtering plant, it's critical that when the animal is eviscerated that a gut isn't split and the insides of the viscera is scattered through the meat because it'd contaminate itthat's critical. We go clear on to the critical control point of a kitchen and tell a housewife that it's critical that she keep the meat cold enough and keep it clean. The two main things in the kitchen are temperature and cleanliness. Our company talks about critical control points from birth clear through to the kitchen, conception to consumption, you might say. The industry is talking about critical control points, the HACCP Program, and today, as we speak, the whole industry is talking about that, but they're only talking about the meat part of it. They never talk about the kitchen part. They never talk about the animal part. We have always believed that there needs to be control from conception to consumption. Developing the testing system As we got more and more ranchers involved and scattered over more states, we decided to instutute more tests. We test blood and urine when the cattle are alive. We test the feed and the water that they eat, and after the cattle are killed we do bacteria tests on all the carcasses. We do kidney tests for antibiotics, fat tests for pesticides, and herbicides, and also tests for antibiotics in the feed. 65% of the land mass of the world is grass

So, of the world's natural resources, oil, gas, minerals, water, land, timber, grass, air, number seven is my passion, that's grass. Grass covers 65% of the world's land mass. And those that say that ranchers should be raising grain for hungry people on these grasslands need to study their lessons a little more because the land is in its best use right now for 3 reasons. It's impossible to raise grain for 1 of these 3 reasons: the terrain is wrong, or the climate is wrong, or the precipitation is wrong. There's a lot of places where all 3 are wrong to raise grain. Grassland management We have found that proper grass planned rotational systems for grassland management are a lot better now than what we were using in the 1950s, or my Dad was doing prior to that, or my granddad and great granddad were doing prior to that. We were just turning cattle out on a piece of range or in a pasture, and leaving them all summer. We found that if we would take say a hypothetical area of about eight miles by five miles where they had run 200 cattle for four months during the growing season, that if they would divide that area into say five pastures or three pastures or four, and put all of the cattle in one pasture for a time, and take them all out and put them in another pasture for a time, and take them all out during that growing season, that the grass density increased a lot. The whole range was in a lot better condition. A better condition is defined as having more grass density of desirable grasses for that climate. We found since 1960 that rotational systems really increased the productivity of that particular piece of ground, which is good news for everybody everywhere. The theory is grass needs some kind of rest during the growing season. I call it `range on the rebound' because everybody especially in the U.S. is concerned about all the public land and many on the East Coast and in different environmental groups are thinking that ranchers are still raping the land. The reason this system works, and it's a first grade or kindergarten reason, is that livestock are planting machines. Their hooves break up the crust and ground and allow grass to penetrate and little grass seedlings to start to grow. |

| Published in In Motion Magazine - November 16, 1997 |

If you have any thoughts on this or would like to contribute to an ongoing discussion in the  What is New? || Affirmative Action || Art Changes || Autonomy: Chiapas - California || Community Images || Education Rights || E-mail, Opinions and Discussion || En español || Essays from Ireland || Global Eyes || Healthcare || Human Rights/Civil Rights || Piri Thomas || Photo of the Week || QA: Interviews || Region || Rural America || Search || Donate || To be notified of new articles || Survey || In Motion Magazine's Store || In Motion Magazine Staff || In Unity Book of Photos || Links Around The World NPC Productions Copyright © 1995-2020 NPC Productions as a compilation. All Rights Reserved. |

And they said "Well, we don't want to start a big controversy in the industry, we're mostly ranchers and farmers". I said "Well I'm not a radical, I don't like to do that either, but we can change some things and satisfy our customers, we're not satisfying our customers".

And they said "Well, we don't want to start a big controversy in the industry, we're mostly ranchers and farmers". I said "Well I'm not a radical, I don't like to do that either, but we can change some things and satisfy our customers, we're not satisfying our customers".

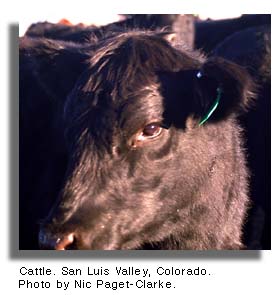

They carry this little white tag in their ear all their life. The mother cow's got one too in her ear but there's hair over it so you can't always see it. We brand them so that we can identify them when they're loose on these big ranges.

They carry this little white tag in their ear all their life. The mother cow's got one too in her ear but there's hair over it so you can't always see it. We brand them so that we can identify them when they're loose on these big ranges.